Among the various development departments within Mazda, the "Vehicle Research Department Craftsmanship Development Group" researches human senses and creates the texture and operability of the car. . The group, which was established in 2001, is in charge of the sensibility area such as the appearance and texture of the interior and exterior, and the ergonomics area such as the driving position.

Among them, it is said that "model-based development (MBD)", which performs advanced development and performance evaluation processes with virtual simulation, is being used. MBD is mainly used for engine development and control development such as control units, but how is it incorporated? We interviewed Kenta Kubo, chief engineer of the same group.

We check whether the designer's drawing achieves high usability and whether it can withstand the actual usage scene. Other manufacturers also have departments that do this. Most of them are integrated into the design department, but Mazda says they are separate. The design department is in charge of appearances such as colors and shapes, as well as styling. The craftsmanship development group is responsible for feel, material quality, and usability.

"The beautiful and cool things that the design department creates are put into actual scenes to verify whether they are really easy to use. Cool things are edgy in many ways. (laughs) And most of them are shining.The fact that they are shining means that they are dazzling.Therefore, we have to consider the characteristics of human beings so that they do not hurt when touched and do not become dazzling when exposed to light. Since what we are creating is a tool called a “moving body,” in order to achieve a balance that does not interfere with the human senses and yet is beautiful, we separate the human-centered thinking from the design sensibility. I am

By dividing into different departments, it is possible to proceed with development while checking each other alternately. Rather than simply making people feel comfortable, they share the common concept of “providing a sense of well-being and comfort,” which is the goal of both Mazda brands. In the past, this was expressed as ``high quality. I want to support people who are interested in and act on ", so I'm doing the main thing right now."

Kenta Kubo Chief Engineer is also a psychologist. Previously taught at a universitySix textures can be mentioned for the interior. "Reflective texture" that reflects the sunlight and gives it a texture. "Luminous texture" related to displays and lighting. A "tactile feel" that is typified by the feeling of touch in a room. "Operability" related to the operation of switches. "Operating texture" related to parts that move electrically, such as power windows and mirrors. Then there is the “fragrance texture” that provides a pleasant fragrance to the interior of the vehicle. All of these are combined to create a sense of space.

What I heard in detail this time is about the development of the so-called "visual area", the so-called "reflection texture". "Naturally, the design department is also involved in this. We want to use beautiful decorations and upholstery. We want to create a lively and comfortable cabin by doing so. Of course, we do too!", but we have to be careful. One of the things is that it's "dazzling."Light comes in and is reflected by the decorations, and if the interior is made of white leather, the reflection will be stronger.I made a prototype car and took it to Arizona (in the United States), for example. When I went there, there were quite a few times where I was like, 'Wow, it's so bright!' Even so, it's a mutual interaction with the sunlight, so at the time I didn't know until I made it."

MBD is currently used to solve these difficulties and losses. By putting data into a model and simulating on the data, it is possible to understand the state of the vehicle without prototyping.

But it's actually not that simple. Of course, it is necessary to eliminate unpleasant reflexes, but it is also necessary to comprehensively evaluate all situations.

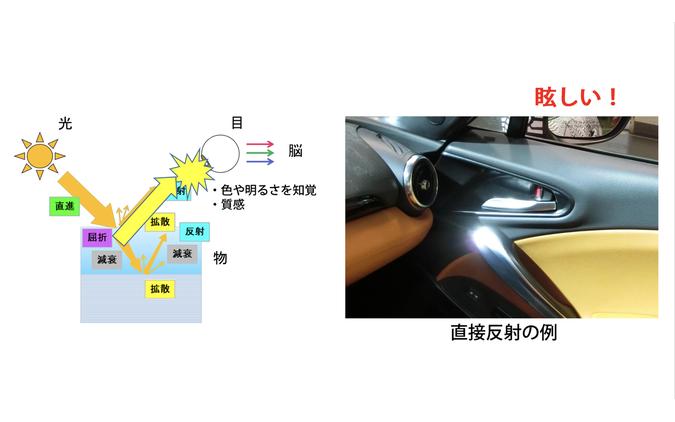

In the same group, reflection is defined by dividing it into two types. One is "direct reflection". It is a phenomenon in which the sunlight reflected on the decoration or the strong light from the lighting directly enters the eye, making it dazzling and annoying.

Sunlight basically goes straight, but when combined with the environment inside the car, the movement after that becomes special. Refraction, attenuation, diffusion, etc. occur, creating complex reflections. Metals convert light into heat, but metal coatings do not, so reflections are felt more strongly. There is no end to calculating and verifying all these on your own.

Direct ReflectionTherefore, the necessary conditions for the simulation are prepared. First of all, "sunlight incident data". The difference in the intensity of sunlight in different areas is due to the angle of the sun (the position of the sun illuminating the area). Therefore, if we could control the angle and calculate the sunlight data for each angle, it would be possible to reproduce sunlight all over the world.

Next, "light reflection data of the shape of the object". For example, protruding areas are strongly reflective, and concave areas are highly diffusive. And "light reflection data of the surface material". Data for each material including transmittance, such as metal, metal coating, and parts of metal that differ depending on the material.

Finally, "measurement data that humans feel dazzling". It is a calculation of whether the light is really dazzling to people, and how painful it would be if it got into the eyes. These data are modeled to simulate antiglare properties.

In the simulation, you can make the sun exist from various places in the 3D drawing (inside the car) and illuminate it. When you shine light on it, the result is clearly shown in a line.You can see the strength of the reflection and the movement of the object directly into the human eye.”

Parts subject to this include the center louver decoration, door grip decoration, shift panel ring, and door trim color panel.

Example of direct reflection``We have a huge facility called artificial sun in our company, so we were also doing things like illuminating it and reproducing it. There may be differences depending on the person, so we decided to create a system that can make quantitative judgments.”

Data such as human body shape, physique, and eye position are also incorporated into the model. Assuming that all kinds of people will drive (ride), any person can determine the point where it is not dazzling.

Let's look at a concrete example that incorporates the model of everyone. The center louver shown below (CG image) was simulated and found to be extremely dazzling when set to the hours when the sunlight is strong. How much do you want to change the shape? If you overdo it, you may not get the beauty that the designer is looking for. Therefore, the intensity of light is digitized. "When I used a candela as a measurement value for quantifying light, it is now 480,000 candela. And if the lower part of the center louver is removed, the value drops to about one-third at once. By incorporating such shape changes, we were able to eliminate the glare without damaging the design.”

Quantitative evaluation of the effect of shape change through the model (the small figure on the upper right is a cross section = a view from the side). Based on the hypothesis that brightness, area, background brightness, etc., are related to how glare is perceived, we have established a judgment index and set a target point for development. The important part is whether it is good or not. “In other words, data on mechanical physical characteristics is already available in the world. However, the unusual thing about Mazda’s MBD is that it collects all of it and uses it as an indicator of how people feel about it. It is characterized by being able to calculate by including the characteristics ofContinuing on, another "indirect reflection". This refers to a phenomenon in which light that hits an object hits the windshield and jumps into your eyes.

For example, if you compare the "Axela" (previous Mazda 3) and the current "Mazda 3", you can see many changes in the upper part of the instrument panel. The red part in the left figure, the speaker, differential grille, around the center display, column cover, etc., caused visual noise due to differences in parting, color, and luster. For this reason, we changed the layout of the speakers and differential grille without sacrificing functionality, and reduced visual noise by downsizing and integrating related parts. Eliminates indirect reflection due to reflection on the windshield.

The Axela (previous Mazda 3) on the left and the current Mazda 3 on the rightThe indirect reflection model requires advanced work to create it by looking at the transmission information of the glass and calculating the reflection while considering attenuation etc. is. In addition to reflection data, we also have to model the reflection and transmittance of window glass, as well as the amount of annoyance and contrast when overlapping with the outside world (surrounding scenery).

Another example is the medium-sized SUV "CX-9" sold in the North American market. “The greater the contrast with the outside world, the more intense the reflection. Conversely, if there is not much contrast, you don’t have to be so conscious of it. We set the most severe scene data, such as appearing alternately, and created it. To find the threshold, cut a cross-sectional view such as ``A-A''' and ``B-B''' like the image and look at the luminance distribution of each part."

Comparison between actual machine (left) and simulation (right). Numerical verification of the difference with the actual device, which can be reproduced with almost the same appearance (brightness ratio, appearance of the image) except for the blurring of the background due to the resolution of the shooting camera. The surface luminance distribution is also at almost the same levelWhen comparing the data of the actual machine and the simulation data of the model, almost the same reproducibility is achieved. Regarding the coarseness of the image resolution and the difference in resolution (the model has a higher resolution, but the human eye does not actually care about such fine details), it is said that it will be improved by increasing data in the future.

Comparison between real machine and simulation"The difficult thing is how to collect data. Algorithms that can be used for simulation basically exist. It's expensive, but if you buy it, you can manage it. However, the key to MBD from now on is what kind of data you actually have and what kind of data you use as training data to create a judgment formula. It's important to be able to make it as close to humans as possible.By incorporating MBD, the development speed of the vehicle has increased significantly.However, our goal is to improve the accuracy and shorten the development period."